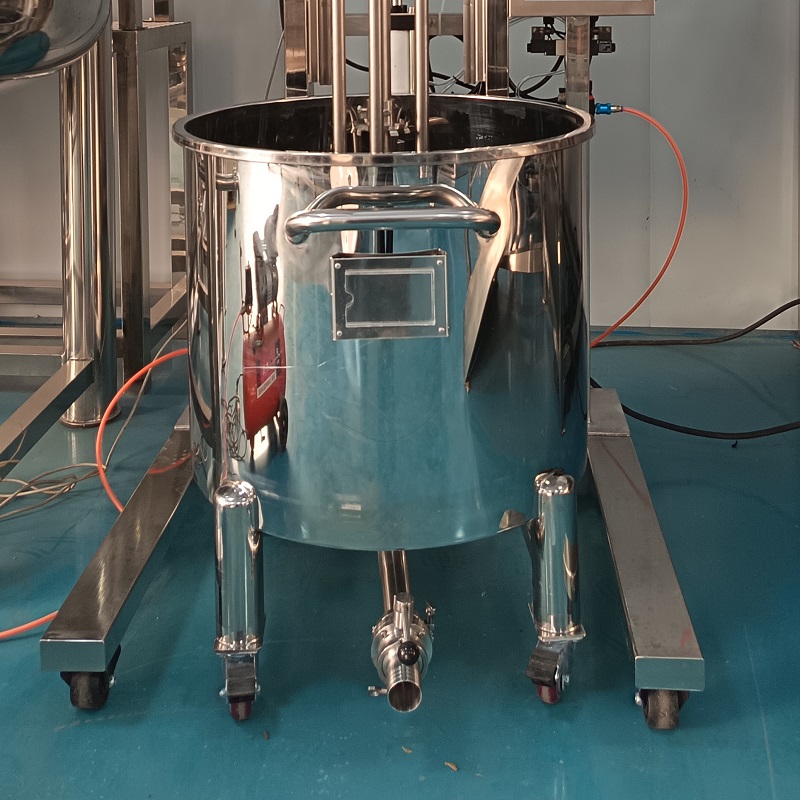

High Shear Mixer Homogenizer

# High Shear Mixer Homogenizer – Precision Mixing Solutions

What Is a High Shear Mixer Homogenizer?

A high shear mixer homogenizer is a powerful industrial mixing device designed to emulsify, disperse, and homogenize materials with intense mechanical shear. Ideal for industries like pharmaceuticals, cosmetics, food, and chemicals, it ensures uniform particle size and stable product consistency.

Key Benefits of YUANYANG High Shear Mixers

- Superior Homogenization: Achieves fine, uniform particle distribution for consistent product quality.

- High Efficiency: Rapid mixing reduces processing time and energy costs.

- Durable Construction: Made with high-grade stainless steel for corrosion resistance and longevity.

- Versatile Applications: Suitable for liquids, creams, gels, and suspensions.

Why Choose YUANYANG’s High Shear Mixers?

As a leading China-based industrial mixer manufacturer since 2008, YUANYANG delivers:

- CE-Certified Safety: Compliant with EU standards for reliable performance.

- Custom Solutions: Tailored mixing systems for diverse production needs.

- Turnkey Support: Free technical training and installation assistance.

Applications Across Industries

- Cosmetics: Smooth emulsions for lotions and creams.

- Pharmaceuticals: Uniform drug suspensions and ointments.

- Food & Beverage: Stable sauces, dressings, and dairy products.

- Chemicals: Efficient dispersion of pigments and additives.

Trust YUANYANG for Reliable Mixing Technology

With advanced R&D and strict quality control, YUANYANG’s high shear mixer homogenizers ensure optimal performance. Contact us for customized mixing solutions and one-stop production line support!

Brand: YUANYANG | Since 2008 | CE-Certified Industrial Mixers

high shear mixer homogenizer Display

How does the rotor and stator work?

When the equipment is running, the rotor drives the blade to rotate at a high speed, generating a strong centrifugal force field, and forming a negative pressure zone in the center of the rotor, which inhales the material liquid. Under the action of centrifugal force, the material spreads from the center to the four sides, and is subjected to the stirring and shearing action of the blades during the diffusion process. The material is subjected to further shearing action in the narrow gap between the end face of the blade and the inner side of the stator tooth ring, and then enters the narrow gap between the rotating tooth and the fixed tooth of the inner ring, and is affected by mechanical force and hydrodynamics effect, resulting in shearing, friction and impact, so that dispersed phase particles or droplets are broken. As the linear speed of the tooth is gradually increased from the inner ring to the outer ring, the crushing environment of the material is continuously improved, and the purpose of homogenizing emulsification is finally achieved.

Can I replace the screw model of the auger filler to pack different weight in one machine?

Yes, we can customize different screw models for the powder filler, and the screw models are replaceable.

What’s the filling range of this semi auto filler?

There are different sizes of air cylinders. Therefore there are the following filling range:5-60g, 10-120g, 20-200g, 30-300g, 50-500g, 100-1000g, 200-2000g, 300-3000g, 500-5000g. Please tell the minimum bottle and maximum bottle capacity, suitable types of filling machine model will be recommended.

Can you make the leg longer, I need a higher discharge outlet?

Yes, the tank legs length is customized as well as the discharge outlet height.

Do you use brand parts for the mixing tank?

Yes, our we cooperate with core parts brand, such as Siemens motor, Beide motor, ABB motor, Delixi electricity, Schneider Electric, Delta frequency converter, Siemens PLC ,Mitsubishi touch screen, Mitsubishi frequency converter, German mechanical sealing, NSK bearing...

Yuany’s philosophy is quality first, service first, thus we get a good reputation in the market.

Automatic Multi-Head Piston Filling Machine for Jar for Sale

Automatic Multi-Head Piston Filling Machine for Jar for Sale

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for Sale

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for Sale

Automatic Single Head Rotor Pump Filling Machine with Liquid Feeder for Sale

Automatic Single Head Rotor Pump Filling Machine with Liquid Feeder for Sale

Automatic Multi-Head Magnetic Pump Anti-corrosive Filling Machine for Sale

Automatic Multi-Head Magnetic Pump Anti-corrosive Filling Machine for Sale

Automatic 4 Heads Detergent Filling Machine for Sale

Automatic 4 Heads Detergent Filling Machine for Sale

Automatic Multi-Head Piston Filling Machine for Jar for Sale

Automatic Multi-Head Piston Filling Machine for Jar for Sale

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for Sale

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for Sale

Automatic Single Head Rotor Pump Filling Machine with Liquid Feeder for Sale

Automatic Single Head Rotor Pump Filling Machine with Liquid Feeder for Sale

Automatic Multi-Head Magnetic Pump Anti-corrosive Filling Machine for Sale

Automatic Multi-Head Magnetic Pump Anti-corrosive Filling Machine for Sale

Automatic Pump Head Feeding and Capping Machine for Sale

Automatic Pump Head Feeding and Capping Machine for Sale

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712