Innovative Equipment for Cosmetic and Personal Care Product Manufacturing

Cosmetic and Personal Care Industry production machinery solution Solutions

Yuanyang Machinery Equipment understands the critical importance of precision, efficiency, and consistency in the production of cosmetics and personal care products. With over a decade of experience in machinery manufacturing and formulation processes, we provide comprehensive equipment solutions tailored to meet the evolving needs of the cosmetics and personal care industry. Our state-of-the-art equipment simplifies production processes, ensuring high-quality, safe, and compliant products that exceed customer expectations.

Main Equipment of Cosmetics Production Line

dvantages of Yuanyang mixer Machinery Equipment Solutions

Customization Options

We offer tailored solutions to meet your specific production requirements for cosmetics or personal care products, including customized machinery design and process optimization.

Precision and Efficiency

Our advanced equipment ensures high precision, reduces material waste, and improves product consistency.

Compliance and Safety

All equipment is manufactured to industry standards, ensuring compliance with cosmetic production regulations such as GMP and ISO standards.

Scalability

Whether you are a startup or an established cosmetic manufacturer, our equipment solutions are scalable to grow with your business.

Are You Looking for A Reliable Supplier of Mixers?

Feel free to write us about product queries or ask for support anytime, we'd love to help. Didn't find the right product or want any recommendations? Contact us today!

Benefits of Using Yuanyang mixer Machinery Equipment in Cosmetic and Personal Care Manufacturing

Choosing Yuanyang Machinery Equipment enhances your production process in numerous ways, improving product quality and optimizing production efficiency.

The Role of RO Water Treatment in Cosmetics

Providing High-Purity Water

· RO membranes remove dissolved solids (TDS), heavy metal ions, organics, and microorganisms, delivering high-purity water.

· Ensures water is free from impurities and contaminants, minimizing skin irritation.

Improving Product Quality

· Water purity directly impacts the quality and stability of cosmetic products.

· High-purity water aids in dissolving and dispersing ingredients, preventing sedimentation, stratification, or spoilage.

Extending Shelf Life

· Eliminates microorganisms and bacteria, reducing contamination risks.

· Prevents product degradation caused by impurities or biological load.

Reducing Production Risks

· RO water minimizes contamination, especially for sterile or sensitive formulations (e.g., eye care and baby care products).

· Enhances equipment cleanliness, avoiding residue buildup in pipelines or containers.

Meeting Regulatory Requirements

Cosmetic production has strict water requirements, such as those specified by the China Cosmetic Safety Technical Specifications and GMP standards, necessitating pharmaceutical-grade purified or RO water.

RO Water Treatment Processes in Cosmetic Manufacturing

Multi-stage filtration ensures water purity meets stringent standards.

Common Applications in Cosmetic Production

Water-based Products: Toners, mists, cleansers, and conditioners use RO water as a base ingredient.

Formulation Solvents: RO water ensures even dissolution of raw materials, minimizing impurities.

Cleaning Processes: For equipment, containers, and pipelines, ensuring no residual impurities.

Sterile Production: Sensitive products (e.g., eye creams, medical masks) require sterile water; RO systems combined with sterilization equipment fulfill these needs.

Efficient Homogenization and Emulsification

Vacuum Homogenizing Emulsifiers

Ideal for creams and lotions, ensuring product stability and texture.

High shear and mixing power deliver uniform blending, preventing particulates in formulations.Vacuum operation minimizes air incorporation, reducing oxidation risk and extending shelf life.

Homogenizing Mixers

Suitable for liquids and semi-solids like shampoos, body washes, and conditioners.

oPrecisely controlled speed and shear forces ensure uniformity, guaranteeing consistent and high-quality finished products.

Sterile Storage Tanks

Applications

Key Features

Capacity options

Ranges from 100L to 50,000L.

Optional functionalities

Temperature control and agitation.

Certifications

Compliance with GMP, FDA, and other standards.

Expandability: Modular designs to accommodate future upgrades.

Precision Filling Capabilities

Cream and Liquid Bottle Fillers & Bag Fillers

High-accuracy filling reduces waste and ensures consistent volume.

Handles materials of varying viscosities, from free-flowing liquids to thick creams.

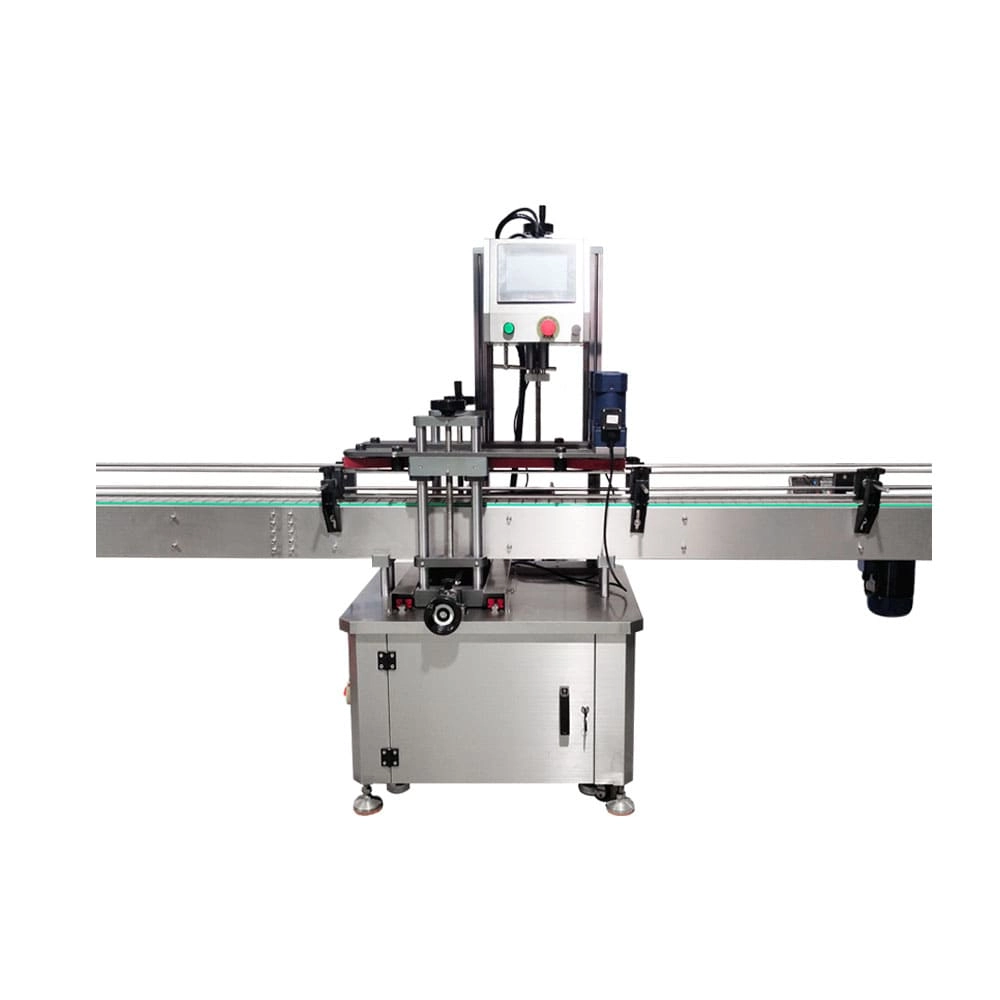

Reliable Capping Sealing and Packaging

Capping Machines / Tube Sealing Machines / Aluminum Foil Sealing machines

Ensures airtight sealing for products, maintaining safety and hygiene.

Delivers clean, aesthetic packaging for tubes or bottles.

Brand Visibility and Regulatory Compliance

Labeling Machines / Coding Machines

High-speed, precise labeling enhances product presentation and ensures regulatory compliance.

ccurately prints batch numbers, expiration dates, and other details on diverse packaging materials, ensuring traceability and compliance. The coding process is quick and accurate, adaptable to a variety of materials. Whether it's glass, plastic, or paper packaging, it ensures clear and durable markings.

AUtomatic Filling Cappling Labeling Line

Why Choose Yuanyang Machinery for Cosmetic and Personal Care Production Lines?

One-Stop Solution

Yuanyang Machinery provides a complete set of production solutions, from raw material processing, homogenizing and emulsifying, to filling, labeling, and coding. Our equipment supports full automation throughout the production process of cosmetics and personal care products. With integrated production equipment, companies can efficiently complete multiple steps on the same production line, reducing switching time and labor costs while significantly improving production efficiency and capacity.

Enhanced Product Stability and Consistent Quality

Our mixing, emulsifying, and filling equipment features high precision and automated control, ensuring consistent product quality across every batch. The advanced control systems continuously monitor production parameters, preventing formula inconsistency or material wastage, helping to produce high-quality, consistent products.

Reducing Production Costs and Improving Efficiency

With Yuanyang's high level of automation, manual intervention and labor costs are significantly reduced. The automation system minimizes human error during the production process while boosting output. The durability and ease of maintenance of our equipment also further lower long-term operational costs, ensuring continuous efficient production line performance.

Meeting Diverse Production Needs

Whether producing different product types or handling special formulations, Yuanyang's equipment is adaptable. The equipment supports quick production line switching and is suitable for manufacturing various cosmetics and personal care products, helping brands meet the diverse consumer demands in the market.

Types of Ingredients Our Cosmetic Production Equipment Can Mix

Yuanyang’s cosmetic production equipment can mix a variety of ingredients, covering a wide range of formulations from solids to liquids, and fully supporting the production of all types of cosmetics and personal care products.

Solid Ingredients

Our equipment efficiently processes and disperses solid particles, such as mineral powders, exfoliating particles, microcrystalline cellulose, etc., used in the production of scrubs, powdered cosmetics, or skincare products containing particles.

Powdered Ingredients

Designed for handling ultra-fine powders like pigments, pearl powder, talcum powder, etc., commonly used in the production of masks, foundation, dry shampoo sprays, etc., ensuring uniform powder distribution.

Slurry-like Ingredients

Capable of processing thick and particle-containing slurry substances, such as mineral mud masks, volcanic ash, and mud cleansers, our equipment ensures uniform mixing of slurry and other liquid ingredients, resulting in a smooth and delicate texture.

Liquid Ingredients

Efficiently blends liquid ingredients, including water phases and oil phases, used in the production of lotions, serums, toners, etc., ensuring stability and preventing separation of various liquid formulations.

Viscous Paste Ingredients

Capable of handling high-viscosity paste ingredients, such as creams, conditioners, and toothpaste, ensuring thorough mixing and even distribution, achieving the ideal thickness and smoothness of the product.

Emulsions and Gel Ingredients

Yuanyang’s equipment can process various emulsions and gel-like substances, such as lotions and gels. It is suitable for producing moisturizing lotions, gel serums, eye care products, ensuring stable, uniform, and non-separating emulsions and gels.

Ointments and Creams

Designed for high-oil-content and thick-textured ointments and creams, such as hand creams, lip balms, and therapeutic ointments, the equipment ensures thorough mixing of oils and other ingredients, providing the ideal texture and stability.

Gaseous and Foam Ingredients

Yuanyang's equipment can also handle products requiring mixing with gas, such as foaming cleansers and mousse hair products, ensuring even distribution of gas in the product, resulting in fine and stable foam.

Emulsification Ingredients

Our equipment specializes in the emulsification process, fully blending immiscible ingredients like water phases and oil phases to produce products such as creams, masks, and moisturizers, ensuring the stability of the emulsion system and a smooth, even texture.

Suspension Ingredients

For products containing suspended particles, such as shampoos with pearl ingredients, facial masks with beads, etc., the equipment ensures stable suspension of particles in the formulation, preventing sedimentation, and ensuring even distribution during use.

About Yuan Yang

The professional industrial mixers supplier

YUANYANG is one of the best China-based industrial mixer and blender manufacturers and concentrates on 100% customer satisfaction.

We strive to continually improve on all aspects of our daily operations. What separates us from the competition is not only that we manufacture mixers following the highest quality standards but also that we provide every customer with super service.

YUANYANG has the experience, knowledge and commitment to both quality and service to solve today’s mixing needs and those of the future.

Application Scenarios

FAQs

Cosmetic

Do you provide equipment operation training?

Absolutely. We offer comprehensive equipment operation training, including both on-site and remote training, to ensure your team is proficient in operating, maintaining, and troubleshooting the equipment.

Can the equipment handle organic or sensitive formulations?

Yes. Our equipment is designed to handle various special formulations, including organic, additive-free, and sensitive formulations, ensuring no contamination or degradation during processing.

Do your equipment meet GMP and other industry standards?

Yes. Our equipment fully complies with GMP, ISO, and other international industry standards and can be customized to meet specific regulatory requirements based on different markets and customers.

How do you handle unexpected downtime or failures during production?

Our equipment is equipped with an intelligent fault detection system that monitors the operational status in real-time, automatically alerts and stops operation when issues arise, ensuring safety. Additionally, our technical support team offers 24/7 remote and on-site services to quickly address equipment failures.

Can your equipment integrate with existing production lines?

Yes. Our equipment can seamlessly integrate with your existing production lines, ensuring smooth operation without disruptions.

What is the production capacity of the equipment?

Our equipment supports both small-batch and large-batch production, depending on customer needs. The equipment is highly scalable and can be adjusted according to your production scale.

What maintenance and support do you provide for the equipment?

We provide detailed equipment maintenance guides and offer regular maintenance services to ensure long-term optimal performance. Additionally, we offer quick-response after-sales technical support to resolve any unexpected issues.

How do I choose the right machine for my production needs?

Our experts will analyze your production goals, product types, batch sizes, and packaging requirements to recommend the most suitable equipment, ensuring an efficient and cost-effective production process.

Does your equipment support automated production?

Yes. Our equipment is highly automated, capable of full automation from ingredient preparation, mixing, emulsifying to filling and sealing, greatly reducing manual intervention and increasing production efficiency.

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712